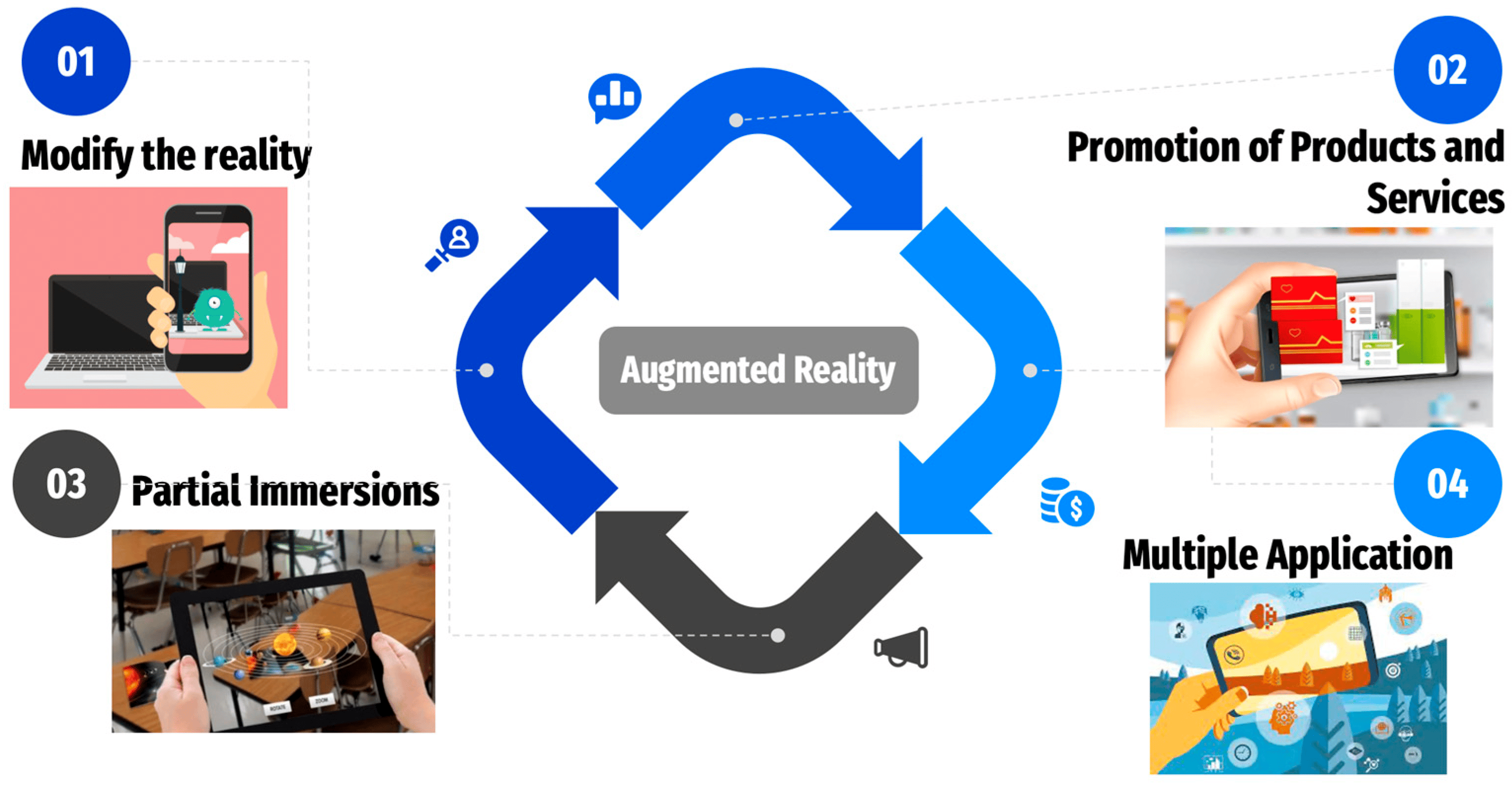

Introduction: The introduction of new technology is causing a major upheaval in the manufacturing sector. Augmented reality, or AR, is one of the most innovative of these. Augmented Reality (AR) allows users to interact with virtual things inside their physical environment by superimposing digital information over the actual world. With its promise of greater efficiency and sustainability, this technology is poised to completely transform the way manufacturing organizations build complicated goods on the shop floor.

Transforming the Shop Floor with AR

On the manufacturing floor, AR offers unprecedented advantages. Technicians can use AR glasses or tablets to visualize assembly instructions directly over the components they are working on. This real-time guidance reduces errors and enhances precision, leading to faster assembly times and improved product quality. For instance, a worker assembling a complex engine can see the exact placement and orientation of each part, ensuring everything fits perfectly.

AR also streamlines training processes. New employees can learn on the job with AR-guided tutorials, reducing the time and cost associated with traditional training methods. This immersive learning experience helps workers grasp intricate procedures quickly, boosting overall productivity.

Enhancing Product Design and Development

Beyond the shop floor, AR significantly impacts the design and development stages of manufacturing. Engineers can create and manipulate 3D models of products in a virtual space, allowing for rapid prototyping and iteration. This capability not only accelerates the design process but also reduces the need for physical prototypes, cutting down material waste and costs.

Moreover, AR facilitates collaborative design sessions, even when team members are geographically dispersed. Designers and engineers can work together in a shared virtual environment, making real-time adjustments and improvements to the product. This collaborative approach ensures that the final design is optimized for both manufacturability and functionality.

AR in Product Delivery and Customer Experience

The benefits of AR extend to the end user as well. For instance, customers can use AR applications to visualize how a product would look in their own environment before making a purchase. This feature is particularly valuable in industries such as furniture and home appliances, where seeing the product in context can influence buying decisions.

Furthermore, AR enhances after-sales support. Customers can use AR-guided troubleshooting tools to diagnose and fix issues with their products. This self-service approach reduces the need for technician visits, saving time and resources for both the company and the customer.

Driving Sustainability with AR

AR is not only about enhancing efficiency and customer experience; it also plays a crucial role in driving sustainability in manufacturing. By minimizing errors and waste on the shop floor, AR contributes to more efficient use of materials and energy. The reduction in physical prototypes and the shift towards virtual testing and design further lessen the environmental footprint of manufacturing processes.

In addition, AR supports sustainable practices by enabling predictive maintenance. By overlaying real-time data onto machinery, AR can help identify potential issues before they lead to breakdowns. This proactive approach extends the lifespan of equipment, reduces downtime, and minimizes the consumption of spare parts and materials.

Conclusion

The integration of Augmented Reality in manufacturing marks a pivotal shift towards a more efficient, innovative, and sustainable industry. From enhancing precision on the shop floor to transforming product design and delivery, AR offers myriad benefits that drive both productivity and sustainability. As this technology continues to evolve, its impact on manufacturing will only grow, heralding a new era of smart, sustainable production. Embracing AR today positions manufacturing companies at the forefront of technological innovation and environmental stewardship, paving the way for a brighter, greener future.

FAQs on the Impact of Augmented Reality in Manufacturing

1. How does Augmented Reality improve efficiency on the manufacturing shop floor?

AR provides real-time, step-by-step instructions overlaid on physical components, reducing assembly errors and speeding up production processes.

2. In what ways can AR be used in product design and development?

AR enables engineers to create and manipulate 3D models, allowing for rapid prototyping, iteration, and collaborative design, which reduces the need for physical prototypes and accelerates the development cycle.

3. How does AR enhance the customer experience in manufacturing?

Customers can use AR to visualize products in their own environment before purchase and access AR-guided troubleshooting tools for easier self-service support.

4. What role does AR play in promoting sustainability in manufacturing?

AR minimizes material waste and energy use by reducing errors and physical prototypes. It also supports predictive maintenance, extending equipment lifespan and reducing the need for spare parts.

5. How does AR streamline training processes for new employees?

AR offers immersive, on-the-job training through guided tutorials, helping new employees quickly learn complex procedures and reducing the time and cost of traditional training methods.